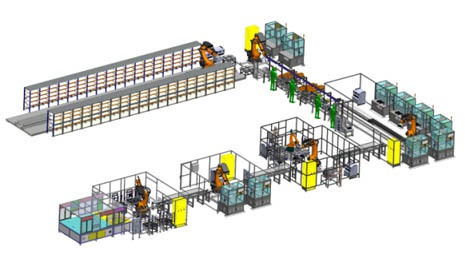

"Green · Green · Quality" as the theme of the new energy battery module and PACK assembly line, flexible to adapt to a number of PACK mixed production, and integrated high-speed truss robots, robot work island, bolt automatic feeding, high-precision measurement and manufacturing Implementation of the system and other advanced manufacturing technology.

Including the core sorting, the core into the shell, the polarity of visual inspection, up and down the stent together, dispensing, plasma cleaning, hot melt, welding, module into the box, bolt automatic feeding and other core equipment, and integrated Intelligent MES Manufacturing Execution System.

Can meet the many types of PACK flexible assembly of mixed production needs, with small batch, high flexibility characteristics;

Can meet the many types of PACK flexible assembly of mixed production needs, with small batch, high flexibility characteristics;

Configuration of high-precision, flexible with the tray, to meet the different needs of the module assembly attitude;

Configuration of high-precision, flexible with the tray, to meet the different needs of the module assembly attitude;

The MES manufacturing execution system can carry out various basic functions such as production planning management, production data acquisition, data query and analysis, material pulling and equipment monitoring and management.

The MES manufacturing execution system can carry out various basic functions such as production planning management, production data acquisition, data query and analysis, material pulling and equipment monitoring and management.

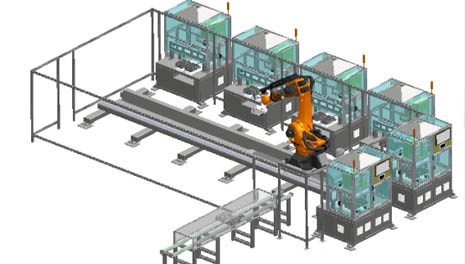

Automatic feeding solution;

Automatic feeding solution;

Electronic billboard technology;

Electronic billboard technology;

Module automatic online assembly;

Module automatic online assembly;

Can automatically complete the co-operation and handling work;

Can automatically complete the co-operation and handling work;

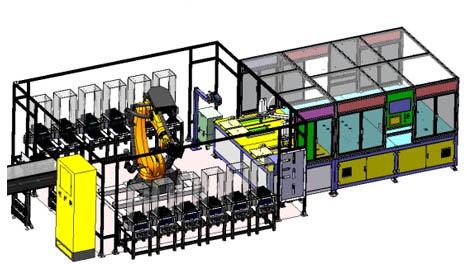

Configuration high-precision DCIR, OCV, EOL, charge and discharge performance measurement test equipment.

Configuration high-precision DCIR, OCV, EOL, charge and discharge performance measurement test equipment.

overall arrangement

Dispenser

welding

Into the shell, shell